Grassi pioneers header and footer on every roll of fabric

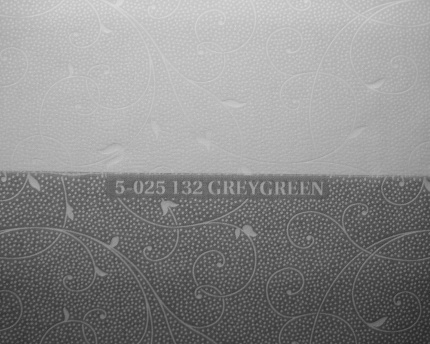

The huge variety of the fabrics they weave, sparkled an idea in the young son of the third generation weaver, Diego Grassi. Instead of pasting or drawing labels to the roll (piece), why not weave it as initial and final part of the jacquard fabric. Such woven label will not peel off, and no material is lost, since initial and ending part of the fabric is ruined in the finishing, anyway.

Tessitura Fratelli Grassi from Vertova, north of Bergamo, Italy, is an innovative family run contract weaving mill.

The huge variety of the fabrics they weave, sparkled an idea in the young son of the third generation weaver, Diego Grassi. Instead of pasting or drawing labels to the roll (piece), why not weave it as initial and final part of the jacquard fabric. Such woven label will not peel off, and no material is lost, since initial and ending part of the fabric is ruined in the finishing, anyway.

Grassi’s production is already fully integrated with ERP SpyderTex from Il Dato. ERP system sends XML requests to ArahWeave CAD server, which converts the fabric file to the appropriate loom file (Staubli JC4, JC5, Bonas).

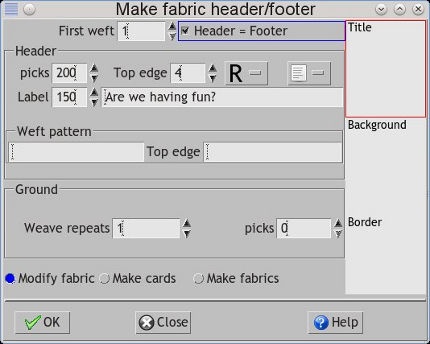

Arahne has upgraded ArahWeave with capability to create text labels on the fly, and weave them as header and footer of every fabric order. Operator on the ERP can choose the text, size and weave for the label. Label ground continues from the main fabric, so that it does not create any problems in finishing.

Grassi’s customers love this feature so much, that they contest the order, if the top woven label is missing. Never again will a weaver walk in the warehouse or finishing department, looking at the rolls of fabric, and not know immediately who ordered them. We accomplished this only with creative use of existing technology (Jacquard, Arahne CAD), no investment in hardware was necessary.